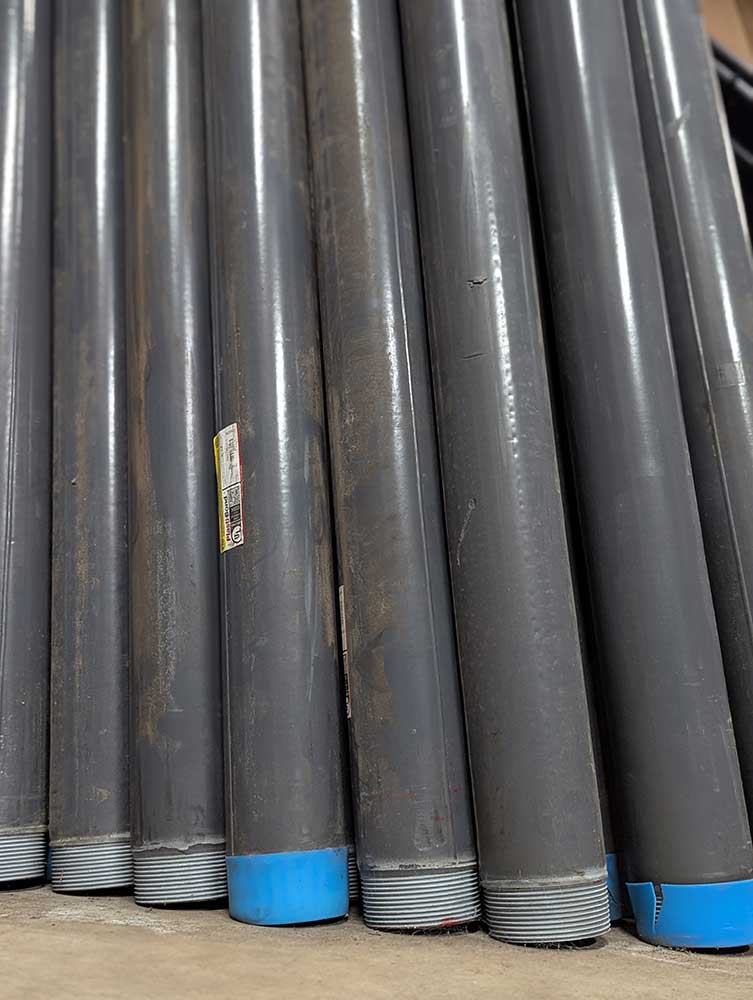

When it comes to industrial electrical installations, choosing the right type of conduit is important for ensuring safety, longevity, and efficiency. PVC coated conduits are a top choice for some specialty industrial applications. As your trusted industrial electric contractor, Hill Electric is here to answer some common questions about PVC coated conduits and their installation process.

What is PVC Coated Conduit?

PVC coated conduit is a type of rigid conduit with an additional protective layer of polyvinyl chloride, or PVC for short. This coating protects against corrosion, perfect for environments where moisture, chemicals, or extreme conditions could otherwise damage standard metal conduits. It’s a preferred choice for industrial settings to protect electrical installations from corrosive environments.

How to Thread PVC Coated Rigid Conduit?

Threading PVC coated conduit requires special attention to avoid damaging the protective PVC layer. The key is to use threading equipment specifically designed for PVC coated materials. Standard threading tools strip away the coating, which reduces the effectiveness and exposes the underlying metal to corrosion. At Hill Electric, our technicians are trained to use the right tools and techniques to maintain the integrity of your conduit installation, even in extreme conditions.

Additional Benefits of PVC Coated Conduit

Beyond its corrosion resistance, PVC coated conduit offers enhanced durability and longevity for industrial applications. The PVC layer provides an extra barrier against physical damage, reducing wear and tear in high-traffic or high-impact areas. Additionally, its non-conductive properties add an extra layer of safety by minimizing the risk of electrical faults or accidental contact. This makes it a reliable choice for facilities prioritizing long-term performance and protection.

Is it OK to Bend PVC Coated Conduit?

The short answer is yes, it is possible to bend PVC coated conduit. However, specialized tools are required to prevent kinking or cracking the PVC layer. The bending process must be done carefully to maintain the conduit’s protective properties. Improper bending can damage the coating, reducing the corrosion and wear resistance of PVC. Hill Electric uses industry-standard benders designed for PVC coated conduit to ensure a seamless installation that stands up to the elements.

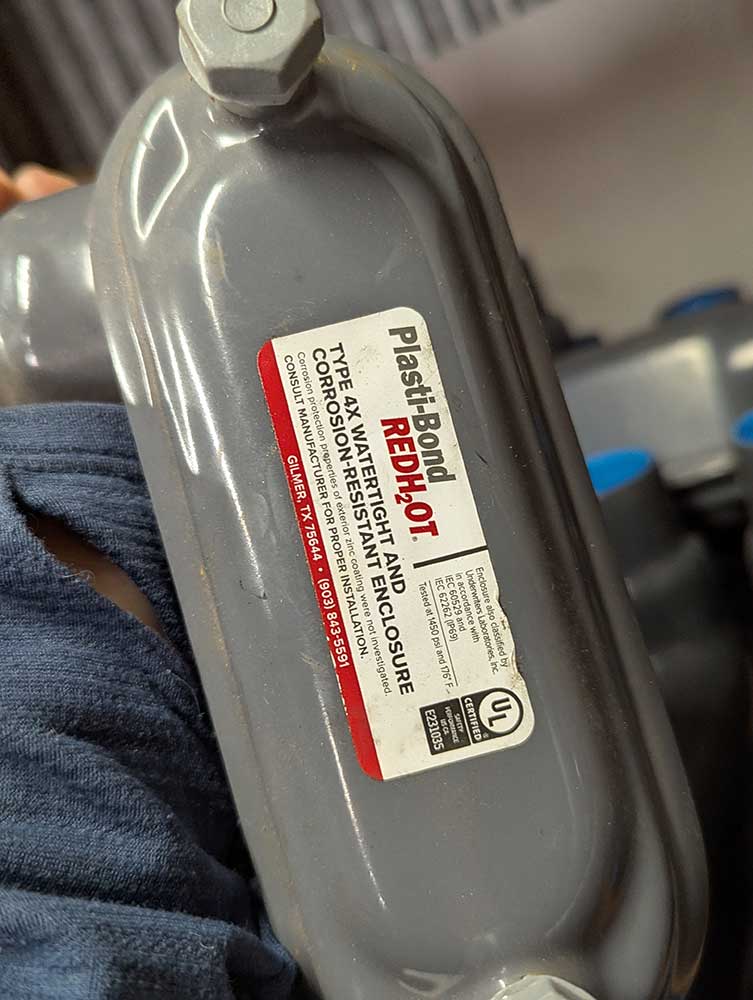

What is the Installation Process for PVC Coated Conduit?

The installation of PVC coated conduit involves several steps to ensure a secure, long-lasting fit:

- Cutting and Threading: The conduit is cut to the required length and threaded using PVC-specific tools.

- Sealing Joints: To prevent moisture ingress, all joints and connections are sealed with compatible, corrosion-resistant compounds.

- Bending: The conduit is bent using specialized equipment to avoid damaging the PVC coating.

- Mounting: The conduit is securely mounted using clamps that do not pinch or damage the coating.

Why Choose Hill Electric for Your PVC Conduit Needs?

At Hill Electric, we have decades of experience installing PVC coated conduit in industrial settings across our service areas. Our team is equipped with the tools and expertise to ensure precise installation that maximizes durability and performance. When you choose Hill Electric, you’re choosing a partner who prioritizes safety, quality, longevity, and customer satisfaction. To learn more about our service offerings, visit our services page.